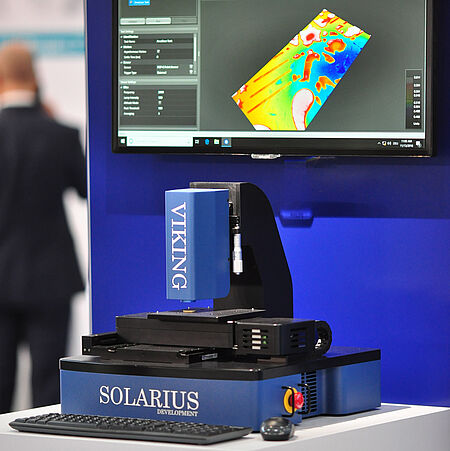

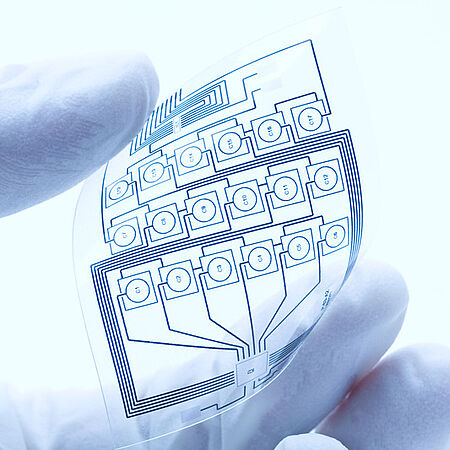

Printing processes place a great deal of demands on the quality of substrates, rollers, paints and printable, electrically conductive materials. As well as the various chemical compositions of paints or electrical conducting materials, microstructures on the rollers and textures of the substrate to be printed determine the color, appearance and functional parameters of text and images, or so-called printed electronics. The descriptive parameters of a printed product are taken into account and verified in the design of the rolls and the choice of materials. Using optical 3D metrology, printing processes can be adapted to match different materials and environmental conditions, as well as technical function parameters can be set and monitored. Solarius 3D optical inspection and metrology tools contribute to make processes reliable and guarantee high quality printed products.